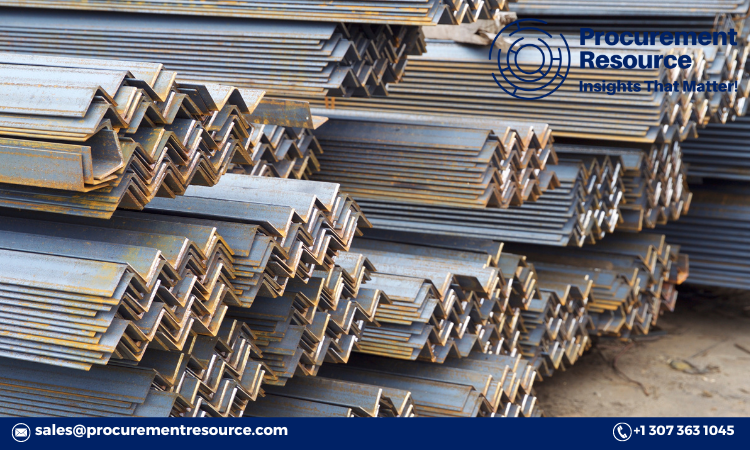

Mild steel angles are one of the most versatile and widely used structural elements in the construction and manufacturing industries. They are essential components in the construction of buildings, bridges, and various types of industrial machinery. Mild steel angles are characterized by their L-shaped cross-section, which provides excellent strength and durability while maintaining a relatively low weight. The production of mild steel angles involves several key steps, each contributing to the overall cost of the final product. In this report, we will delve into the details of the production process, examine the associated costs, and provide insights into the latest news and trends impacting the industry.

Manufacturing Report and Process

The production of mild steel angles begins with the selection of raw materials. The primary raw material used is mild steel, which is chosen for its excellent balance of strength, ductility, and weldability. The process of manufacturing mild steel angles can be broken down into the following key stages:

Request For Sample: https://www.procurementresource.com/production-cost-report-store/mild-steel-angle/request-sample

- Melting and Casting: The production process starts with melting scrap steel or iron in a furnace. Once melted, the liquid metal is cast into large rectangular billets, which are then allowed to cool and solidify.

- Heating: The billets are heated in a reheating furnace to a temperature suitable for hot rolling. This step is crucial as it ensures the metal is malleable enough for the subsequent shaping process.

- Hot Rolling: The heated billets are passed through a series of rolling mills, where they are gradually shaped into the desired L-shaped cross-section. This process involves multiple passes through the rolling mills to achieve the precise dimensions and mechanical properties required.

- Cutting to Length: After rolling, the long lengths of mild steel angles are cut into specific lengths as per the requirements. This is typically done using mechanical shears or saws.

- Cooling and Straightening: The cut pieces are then cooled and straightened to ensure they meet the required specifications for flatness and straightness.

- Surface Treatment: Depending on the application, the mild steel angles may undergo surface treatments such as galvanizing, painting, or coating to enhance corrosion resistance and improve aesthetics.

- Quality Control and Inspection: The final products undergo rigorous quality control checks to ensure they meet industry standards and customer specifications. This includes checking for dimensional accuracy, surface finish, and mechanical properties.

Raw Material Costs

The cost of raw materials is a significant factor in the overall production cost of mild steel angles. The primary raw material used is mild steel, which is derived from iron ore. The cost of mild steel is influenced by various factors, including:

- Iron Ore Prices: The price of iron ore, the primary raw material for steel production, fluctuates based on global supply and demand dynamics. Factors such as mining activities, geopolitical events, and environmental regulations can impact iron ore prices.

- Scrap Steel Prices: In addition to iron ore, scrap steel is often used as a raw material in steel production. The availability and cost of scrap steel can vary based on market conditions, recycling rates, and industrial demand.

- Energy Costs: The production of mild steel angles is energy-intensive, requiring significant amounts of electricity and natural gas for processes such as melting, heating, and rolling. Fluctuations in energy prices can directly affect production costs.

- Labor Costs: Labor costs, including wages and benefits for workers involved in the production process, also contribute to the overall cost of manufacturing mild steel angles.

- Transportation Costs: The cost of transporting raw materials to the production facility and finished products to customers is another important consideration. Factors such as fuel prices, transportation infrastructure, and logistics efficiency can impact these costs.

Latest News

The mild steel angle production industry is continually evolving, with several key trends and developments shaping the market landscape. Some of the latest news and trends include:

- Technological Advancements: Innovations in manufacturing technology, such as automation and digitalization, are enhancing production efficiency and reducing costs. Advanced rolling mills, robotic systems, and real-time monitoring are improving the precision and quality of mild steel angles.

- Sustainability Initiatives: The steel industry is increasingly focusing on sustainability and environmental responsibility. Efforts to reduce carbon emissions, improve energy efficiency, and adopt green technologies are gaining momentum. This includes the development of low-carbon steel production processes and increased use of recycled materials.

- Market Dynamics: The demand for mild steel angles is influenced by various market dynamics, including construction activity, infrastructure development, and industrial production. Economic conditions, government policies, and investment in infrastructure projects play a significant role in shaping demand.

- Trade Policies: International trade policies and tariffs can impact the supply chain and cost structure of mild steel angle production. Changes in trade agreements, import/export regulations, and tariffs on steel products can affect market competitiveness and pricing.

- Supply Chain Disruptions: The global supply chain has faced challenges due to events such as the COVID-19 pandemic, geopolitical tensions, and natural disasters. These disruptions can impact the availability and cost of raw materials, transportation, and production inputs.

- Industry Consolidation: The steel industry has witnessed consolidation through mergers and acquisitions, leading to the emergence of larger, more integrated players. This consolidation can influence market competition, production capacity, and pricing strategies.

Conclusion

The production of mild steel angles involves a complex and multi-faceted process, with costs influenced by various factors ranging from raw material prices to energy and labor expenses. Understanding these cost components is crucial for manufacturers, suppliers, and consumers to navigate the market effectively. Moreover, staying informed about the latest news and trends in the industry can provide valuable insights into future developments and opportunities. As the industry continues to evolve, technological advancements, sustainability initiatives, and market dynamics will play pivotal roles in shaping the production and cost landscape of mild steel angles.