Insects are more than just a seasonal nuisance. In commercial spaces, warehouses, food processing units, hospitals, and even modern homes, flying insects can compromise hygiene, damage goods, and negatively impact customer perception. This is where an Insect Killer Machine becomes an essential investment rather than an optional accessory.

Today’s pest control solutions focus on safety, efficiency, and sustainability. Businesses are moving away from chemical sprays and opting for advanced electric insect control systems. Among the trusted industrial suppliers in this segment, Universal Plastics is known for offering practical solutions that align with hygiene and compliance standards across industries.

In this guide, we’ll explore how an Insect Killer Machine works, its benefits, buyer considerations, and how it complements other industrial protection products like those offered by a PVC Strip Curtain Manufacturer, a Stretch Film Manufacturer, or a Cold Storage PVC Strip Curtain Wholesaler.

Why an Insect Killer Machine Is Essential Today

Flying insects such as flies, mosquitoes, and moths are attracted to light and food sources. In environments like restaurants, cold storage facilities, and packaging units, their presence can:

- Spread bacteria and pathogens

- Contaminate food products

- Damage stored goods

- Create discomfort for staff and customers

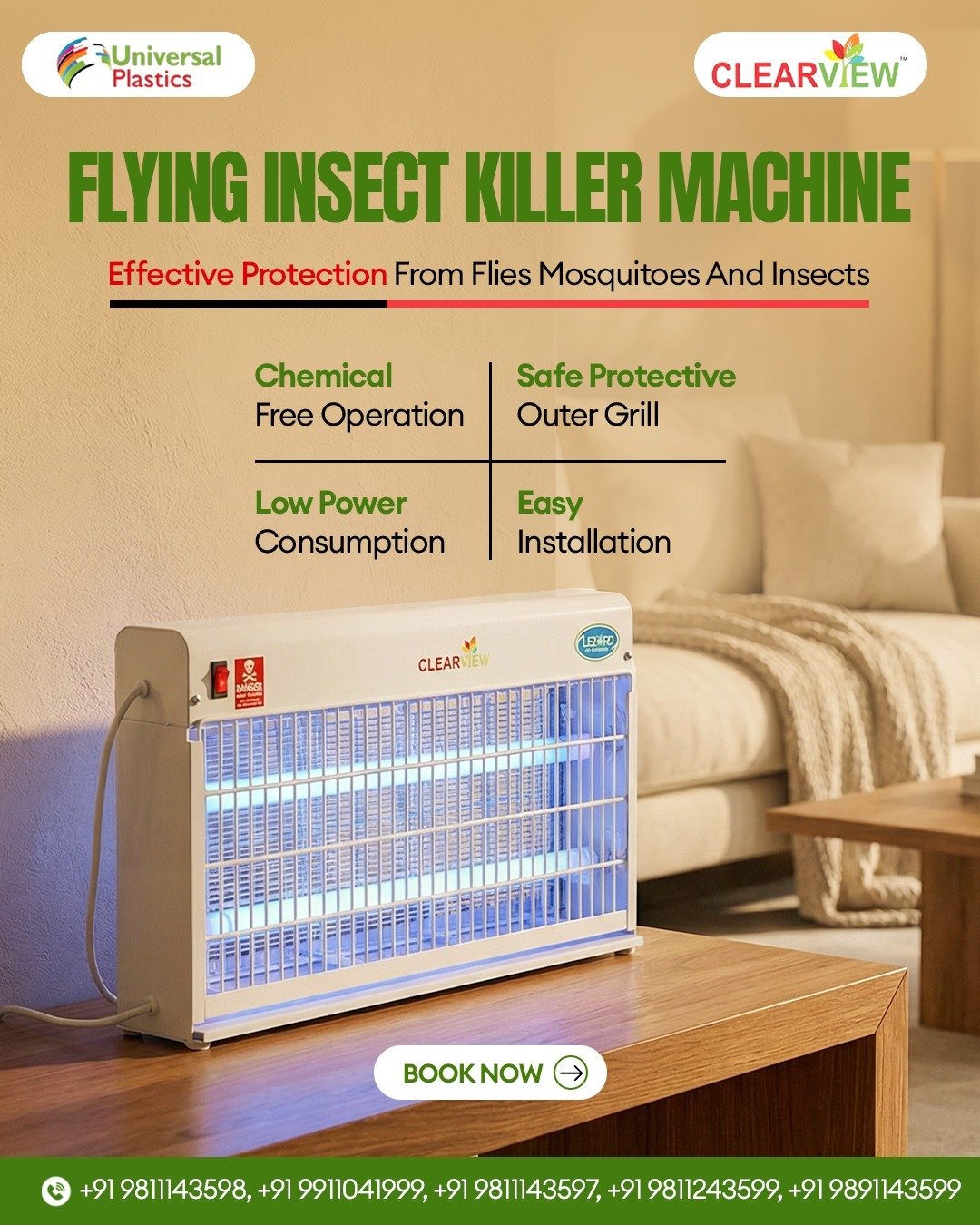

An Insect Killer Machine uses ultraviolet (UV) light to attract insects and eliminate them using electric grids or glue boards. This ensures effective control without harmful chemicals.

For industries handling food, pharmaceuticals, and perishables, installing such machines is often part of hygiene compliance protocols.

How an Insect Killer Machine Works

Understanding the mechanism helps buyers make informed decisions.

1. UV Attraction Technology

The machine emits UV light that attracts flying insects naturally.

2. Safe Elimination Mechanism

Once insects approach the unit, they are either:

- Eliminated via an electric grid, or

- Trapped on adhesive glue boards

3. Easy Maintenance

Most modern systems allow easy tray removal and cleaning, ensuring hygiene.

Manufacturers like Universal Plastics design machines keeping durability and low maintenance in mind, especially for industrial and commercial settings.

Key Benefits of Using an Insect Killer Machine

Hygienic Pest Control

Unlike chemical sprays, an Insect Killer Machine offers non-toxic insect management, making it suitable for sensitive areas.

Cost-Effective Long-Term Solution

While the initial cost may be higher than sprays, it reduces recurring chemical expenses.

Environmentally Friendly

No harmful fumes or residues are released.

Safe for Indoor Use

It can be installed in offices, kitchens, warehouses, and retail outlets.

Continuous Protection

Works 24/7, ensuring uninterrupted pest control.

When combined with physical barriers from a PVC Strip Curtain Manufacturer, businesses can significantly reduce insect entry points.

Complementary Industrial Solutions for Maximum Protection

PVC Strip Curtains for Entry Control

Working with a reliable PVC Strip Curtain Manufacturer helps reduce insect infiltration at entry and exit points. PVC strip curtains:

- Maintain temperature control

- Reduce dust and flying insect entry

- Improve energy efficiency

In facilities like food processing plants, combining strip curtains with an Insect Killer Machine creates a two-layer defense system.

Stretch Film for Product Protection

A Stretch Film Manufacturer provides packaging solutions that protect goods from dust and moisture. While stretch film doesn’t directly eliminate insects, it prevents contamination during storage and transit.

Warehouses that use stretch film along with insect control systems minimize both infestation and product damage risks.

Cold Storage Protection

Cold storage facilities require specialized protection due to frequent door openings. A Cold Storage PVC Strip Curtain Wholesaler supplies heavy-duty strip curtains that:

- Maintain internal temperature

- Limit insect entry

- Reduce energy loss

Pairing these curtains with a strategically placed Insect Killer Machine enhances hygiene standards significantly.

Companies such as Universal Plastics often supply integrated solutions for industrial environments, supporting a cleaner and safer workspace.

Market Trends: Growing Demand for Electric Insect Control

With increasing awareness about hygiene and food safety regulations, demand for the Insect Killer Machine has grown rapidly across:

- Restaurants and cafes

- Hospitals and clinics

- Cold storage warehouses

- Food manufacturing units

- Corporate offices

Government regulations and quality certifications are pushing industries toward chemical-free pest control methods.

Additionally, rising infrastructure development has increased demand for complementary products from a PVC Strip Curtain Manufacturer and Cold Storage PVC Strip Curtain Wholesaler to create comprehensive protection systems.

Buyer’s Guide: How to Choose the Right Insect Killer Machine

Selecting the right unit depends on several factors.

1. Area Coverage

Check the square footage coverage capacity of the machine.

2. Installation Type

Wall-mounted, ceiling-mounted, or portable options are available.

3. Power Consumption

Energy-efficient models reduce operational costs.

4. Safety Standards

Look for shock-proof outer bodies and safe grid designs.

5. Maintenance Requirements

Easy-to-clean trays and replaceable bulbs improve usability.

Brands like Universal Plastics focus on durable materials and reliable performance to ensure long-term functionality.

Common Mistakes to Avoid

When investing in an Insect Killer Machine, avoid:

- Installing the unit near competing light sources

- Ignoring routine cleaning

- Choosing a machine with insufficient coverage

- Neglecting entry-point barriers

For optimal results, combine electric insect control with physical barriers supplied by a PVC Strip Curtain Manufacturer.

Industrial Applications of Insect Killer Machines

Food Processing Units

Maintains hygiene compliance and reduces contamination risk.

Warehouses & Logistics Hubs

Prevents infestation in packaged goods, especially when combined with stretch wrapping solutions from a Stretch Film Manufacturer.

Hospitals & Clinics

Ensures a clean and infection-controlled environment.

Retail Stores & Supermarkets

Improves customer comfort and brand perception.

In integrated facility planning, companies like Universal Plastics help businesses select appropriate insect control systems tailored to their operational scale.

Maintenance Tips for Long-Term Performance

To ensure maximum efficiency:

- Clean collection trays weekly

- Replace UV bulbs as recommended

- Inspect electric grids periodically

- Avoid placing machines near strong airflow

Routine maintenance extends lifespan and improves performance.

Why Integrated Protection Is the Future

Modern facility management focuses on layered protection strategies. Instead of relying solely on an Insect Killer Machine, industries now combine:

- Electric insect control

- PVC strip barriers

- Stretch film packaging

- Cold storage insulation

This holistic approach minimizes risks and improves operational efficiency.

As industrial hygiene standards continue to evolve, companies like Universal Plastics contribute by offering practical, durable solutions aligned with market needs.

Conclusion: A Smarter Way to Maintain Pest-Free Spaces

Maintaining a pest-free environment is no longer optional—it’s a necessity for health, compliance, and customer trust. An Insect Killer Machine offers a safe, effective, and eco-friendly way to control flying insects in commercial and industrial settings.

When paired with solutions from a PVC Strip Curtain Manufacturer, a Stretch Film Manufacturer, and a Cold Storage PVC Strip Curtain Wholesaler, businesses can create a comprehensive protection system.

Choosing a reliable supplier ensures durability, efficiency, and long-term value. If you’re evaluating advanced insect control solutions, exploring options from Universal Plastics can be a practical step toward improving hygiene and operational standards without compromising safety.

Frequently Asked Questions (FAQs)

1. Is an Insect Killer Machine safe for food processing areas?

Yes. Most modern machines are chemical-free and designed specifically for hygienic environments.

2. How often should UV bulbs be replaced?

Typically every 6–12 months, depending on usage and manufacturer recommendations.

3. Can I use an Insect Killer Machine in cold storage?

Yes, but placement should complement PVC strip barriers supplied by a Cold Storage PVC Strip Curtain Wholesaler.

4. Does an Insect Killer Machine consume a lot of electricity?

No. Energy-efficient models are designed for continuous operation with minimal power usage.

5. How can I prevent insects from entering in the first place?

Install PVC strip curtains from a reliable PVC Strip Curtain Manufacturer and ensure proper sealing of entry points along with using an Insect Killer Machine.