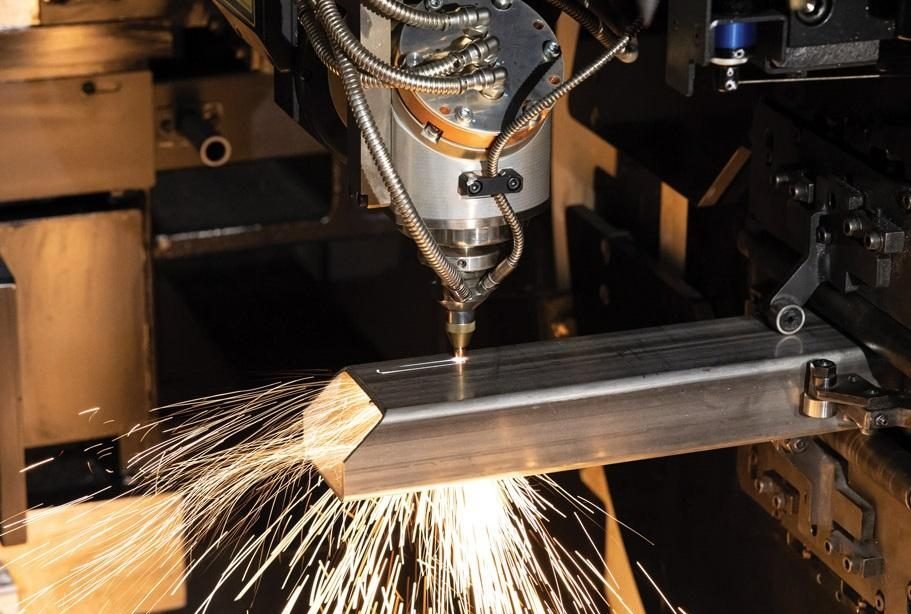

How Laser Cutting is Revolutionizing the Automation Industry

In recent years, the automation industry has witnessed a surge in technological advancements, transforming the way processes are carried out across sectors. Among these advancements, laser cutting technology has emerged as a game-changer. With its ability to deliver unparalleled precision, speed, and versatility, laser cutting has significantly impacted various industries, including manufacturing, robotics, electronics, and aerospace. This article explores how laser cutting is revolutionizing the automation industry and reshaping the future of manufacturing and production processes.

According to a Cutting Equipment Market report, the industry is expected to grow significantly in the coming years.

The Basics of Laser Cutting Technology

Laser cutting is a manufacturing process that uses a high-powered laser beam to cut through materials. The laser beam, typically generated by a CO2 laser, is focused onto the surface of the material, melting, burning, or vaporizing it in a highly controlled manner. This process is used for a wide range of materials, including metals, plastics, wood, glass, ceramics, and textiles.

The key advantages of laser cutting over traditional mechanical cutting methods are precision, speed, and the ability to work with complex designs. Unlike conventional cutting tools, which can wear out and require constant maintenance, lasers provide a consistent cutting edge without direct contact with the material, reducing wear and tear.

Key Benefits of Laser Cutting in Automation

- Enhanced Precision and Accuracy One of the most notable benefits of laser cutting is its exceptional precision. In automated systems, where components need to fit together with tight tolerances, even a slight deviation can result in failure or inefficiency. Laser cutters are capable of producing cuts with micrometer-level precision, ensuring that each part meets the exact specifications required for automation systems. For example, in robotics, precision is critical in ensuring that components such as gears, brackets, and housings fit together perfectly. Laser cutting provides the accuracy needed to create these components with minimal tolerances, reducing the likelihood of errors and the need for costly rework.

- High-Speed Production In the fast-paced world of automation, speed is a crucial factor. Laser cutting technology allows for faster cutting speeds compared to traditional methods. The high energy density of the laser allows it to cut through materials quickly, resulting in shorter cycle times and higher production rates. This is particularly important in industries such as automotive manufacturing, where high-volume production is necessary to meet demand. Laser cutting also reduces the need for manual labor, as automated laser cutting machines can operate continuously, only stopping for maintenance or material changes. This increased efficiency translates into cost savings and shorter lead times, giving companies a competitive edge in a market that demands rapid turnaround times.

- Flexibility and Versatility Another significant advantage of laser cutting in automation is its versatility. Laser cutters can handle a wide variety of materials, ranging from thin sheets to thick metals, without requiring the user to switch tools or machines. This flexibility allows manufacturers to use a single cutting system for different materials, simplifying the production process. Moreover, laser cutting can produce intricate and complex shapes, including those with sharp internal angles and small details. This is particularly valuable in the automation industry, where custom parts and designs are often required for specific applications. Whether it’s cutting precision components for robotic arms or intricate patterns for circuit boards, laser cutting can handle the complexity with ease.

- Minimal Material Waste The precision of laser cutting also means that there is minimal material waste. Traditional cutting methods, such as sawing or punching, often result in excess scrap material. In contrast, laser cutting generates clean, narrow cuts that maximize the use of the material, reducing waste and lowering material costs. This is particularly beneficial in industries that work with expensive raw materials, such as aerospace or electronics, where every ounce of material counts. Additionally, the minimal heat affected zone (HAZ) in laser cutting means that the material around the cut is not significantly altered, preserving the integrity of the material. This results in better material utilization and higher-quality finished products, contributing to sustainability efforts within the automation industry.

- Automation Integration and Smart Manufacturing Laser cutting is naturally suited to integration with automated systems. In modern smart manufacturing environments, laser cutters are often integrated with robotic arms, conveyor belts, and other automation equipment to streamline production. This allows for fully automated production lines where materials are fed into the system, cut, and then moved to the next stage of the process without human intervention. The ability to connect laser cutters to computer-aided design (CAD) and computer-aided manufacturing (CAM) software further enhances their efficiency. These systems allow for precise programming of cutting paths, enabling manufacturers to optimize the cutting process and reduce the risk of errors. Additionally, the real-time data generated by laser cutting systems can be used for predictive maintenance, ensuring that machines are operating at peak efficiency and reducing downtime.

- Cost-Effectiveness and Reduced Labor Costs While the initial investment in laser cutting equipment can be high, the long-term cost savings are significant. Laser cutting systems typically require less maintenance than traditional cutting tools, as there is no physical contact between the laser and the material. This reduces wear and tear on the equipment, extending its lifespan and lowering operating costs. Furthermore, the automation of the cutting process reduces the need for manual labor, freeing up workers to focus on more value-added tasks. In industries with labor shortages or high labor costs, such as electronics or automotive manufacturing, laser cutting provides a cost-effective solution to maintain production levels without the need for additional human resources.

- Improved Safety and Reduced Human Error Laser cutting improves safety by reducing human interaction with the cutting process. Traditional cutting methods often involve the use of heavy machinery that requires operators to be in close proximity to the work area, increasing the risk of accidents. In contrast, laser cutting systems are typically enclosed in protective housing, keeping operators at a safe distance from the machine. The high degree of automation also reduces the likelihood of human error. With laser cutting, once the program is set, the system can operate autonomously, ensuring consistency and accuracy in every cut. This is especially important in industries such as aerospace, where the slightest error can have catastrophic consequences.

Applications of Laser Cutting in the Automation Industry

- Robotics Manufacturing In robotics, laser cutting is used to manufacture a variety of components, including structural parts, brackets, and enclosures. The precision and speed of laser cutting are crucial in ensuring that these components fit together perfectly, allowing robotic systems to function with high accuracy and efficiency.

- Aerospace The aerospace industry relies heavily on laser cutting for the production of lightweight and durable parts. Laser cutting is used to fabricate complex parts from metals such as titanium and aluminum, ensuring the parts meet strict tolerance requirements while minimizing material waste.

- Automotive In the automotive industry, laser cutting is used to create precision parts such as body panels, engine components, and exhaust systems. The ability to cut through various materials, including metals and composites, with high speed and precision makes laser cutting ideal for high-volume automotive production.

- Electronics The electronics industry utilizes laser cutting to produce circuit boards, connectors, and other small components. The ability to create intricate designs with fine details makes laser cutting indispensable for electronics manufacturing, where precision is paramount.

Conclusion

Laser cutting is undeniably revolutionizing the automation industry by offering unmatched precision, speed, versatility, and cost-effectiveness. Its ability to produce high-quality components with minimal waste has made it a valuable tool across a range of industries, from robotics to aerospace and automotive manufacturing. As technology continues to advance, the integration of laser cutting with other automated systems will further enhance production efficiency, reduce labor costs, and drive innovation in the manufacturing sector. The future of automation is undoubtedly bright, with laser cutting playing a pivotal role in shaping that future.