CNC (Computer Numerical Control) machining has revolutionized the manufacturing industry by providing unparalleled precision and efficiency in the production of complex components. China, known for its robust manufacturing capabilities, has become a global hub for CNC machining. The country’s advanced technological infrastructure, skilled labor force, and cost-effective production methods make it an attractive destination for businesses seeking high-quality machining services. In this article, we will explore how CNC machining in China ensures high precision, focusing on the factors that contribute to its success in the global market.

The Rise of CNC Machining in China

Over the past few decades, China has emerged as a leader in CNC machining, thanks to its strategic investments in technology, education, and infrastructure. The Chinese government has prioritized the development of high-tech industries, leading to the rapid growth of CNC machining capabilities across the country. Today, China boasts a vast network of CNC machining facilities equipped with state-of-the-art machinery and staffed by highly trained engineers and technicians.

Advanced Technology and Machinery

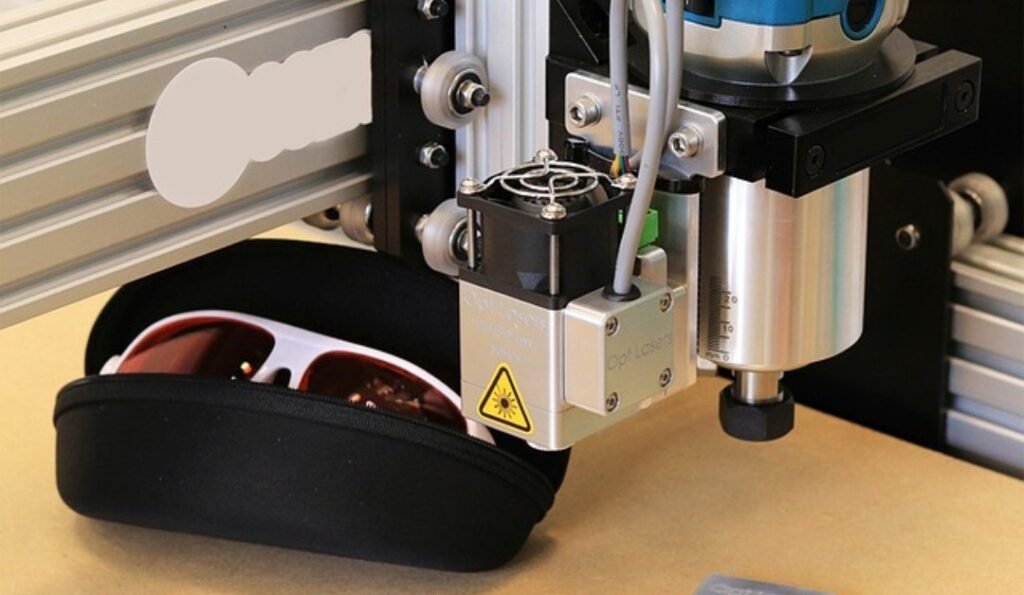

One of the key factors behind the high precision of CNC machining in China is the use of advanced technology and machinery. Chinese manufacturers have access to the latest CNC machines, which are capable of producing intricate parts with micron-level accuracy. These machines are equipped with cutting-edge software that allows for precise control over every aspect of the machining process, from the initial design to the final product.

The use of multi-axis CNC machines is particularly noteworthy in China. These machines, which can operate on multiple axes simultaneously, enable the production of complex geometries that would be impossible to achieve with traditional machining methods. For example, 5-axis CNC machines, which are common in Chinese factories, allow for the creation of parts with complex curves and angles, all while maintaining extremely tight tolerances.

Skilled Workforce

Another crucial factor contributing to the precision of CNC machining in China is the availability of a highly skilled workforce. China has invested heavily in technical education and training programs, producing a large pool of engineers and technicians who are proficient in CNC machining. These professionals are trained in the latest machining techniques and are capable of operating and maintaining advanced CNC machinery.

Chinese CNC machinists are known for their attention to detail and their ability to work with complex designs. They are skilled in interpreting technical drawings and CAD (Computer-Aided Design) files, ensuring that the final product matches the original specifications with high accuracy. This expertise is essential for achieving the high precision required in industries such as aerospace, automotive, and medical device manufacturing.

Quality Control and Standards

Quality control is a critical aspect of CNC machining in China, and it plays a significant role in ensuring high precision. Chinese manufacturers adhere to strict quality control procedures throughout the machining process, from material selection to final inspection. Many Chinese CNC machining facilities are ISO-certified, meaning they comply with international standards for quality management systems.

In addition to ISO certification, Chinese manufacturers often implement their own quality control protocols to meet the specific requirements of their clients. This may include in-process inspections, where parts are checked for accuracy at various stages of production, as well as final inspections using advanced metrology equipment such as coordinate measuring machines (CMMs) and laser scanners.

These rigorous quality control measures ensure that every part produced by CNC machining in China meets the highest standards of precision and quality. As a result, Chinese-manufactured components are trusted by companies around the world in industries where precision is paramount.

Cost-Effectiveness

While high precision is a key advantage of CNC machining in China, cost-effectiveness is another factor that makes it an attractive option for businesses. China offers a unique combination of advanced technology, skilled labor, and competitive pricing, allowing companies to obtain high-quality machined parts at a lower cost compared to other countries.

The cost-effectiveness of CNC machining in China is due in part to economies of scale. China’s large manufacturing sector allows for mass production of parts, which reduces the cost per unit. Additionally, the relatively low cost of labor in China, combined with the high efficiency of CNC machines, contributes to the overall cost savings.

However, it is important to note that the lower cost of CNC machining in China does not come at the expense of quality. Chinese manufacturers are able to maintain high precision while offering competitive pricing, making them a preferred choice for businesses seeking both quality and affordability.

Innovation and Continuous Improvement

China’s CNC machining industry is characterized by a strong culture of innovation and continuous improvement. Chinese manufacturers are constantly investing in research and development to improve their machining processes and enhance the precision of their products. This commitment to innovation has led to the development of new machining techniques and technologies that push the boundaries of what is possible in CNC machining.

For example, some Chinese companies are exploring the use of additive manufacturing (3D printing) in conjunction with CNC machining to create hybrid processes that offer even greater precision and flexibility. Others are investing in advanced automation and AI-driven systems to further optimize the machining process and reduce the potential for human error.

This focus on innovation ensures that CNC machining in China remains at the forefront of the industry, providing businesses with access to the latest advancements in precision manufacturing.

Case Studies: CNC Machining Success Stories in China

To illustrate the precision and capabilities of CNC machining in China, let’s look at a few case studies of successful projects:

- Aerospace Components: A leading aerospace manufacturer partnered with a Chinese CNC machining company to produce critical components for jet engines. The Chinese company used 5-axis CNC machines to produce parts with complex geometries and tight tolerances, ensuring that the components met the stringent requirements of the aerospace industry.

- Medical Devices: A global medical device company outsourced the production of surgical instruments to a Chinese CNC machining facility. The Chinese company implemented strict quality control measures and used advanced metrology equipment to ensure that each instrument met the high precision standards required for medical applications.

- Automotive Parts: A major automotive manufacturer turned to a Chinese CNC machining company to produce precision parts for electric vehicles. The Chinese company leveraged its expertise in multi-axis machining to produce components with complex designs, all while maintaining cost-effectiveness and high precision.

Conclusion

CNC machining in China has established itself as a global leader in precision manufacturing, offering businesses access to advanced technology, skilled labor, and cost-effective production methods. The combination of these factors ensures that CNC machining in China consistently delivers high-precision components that meet the stringent requirements of industries such as aerospace, medical devices, and automotive manufacturing.