Introduction

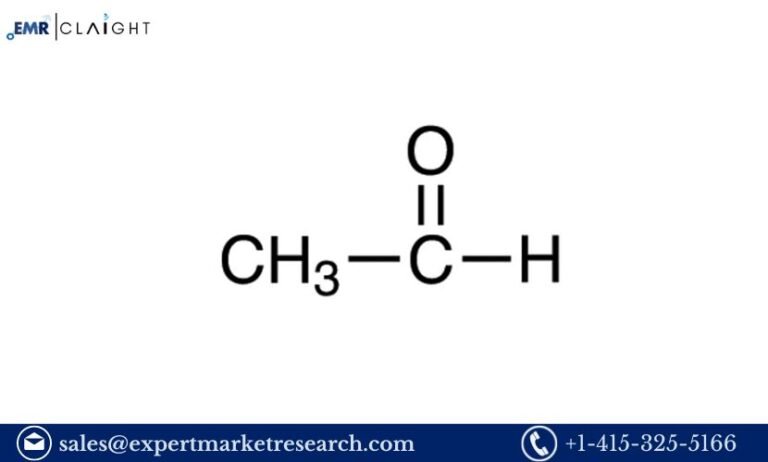

Acetaldehyde is a crucial intermediate chemical widely used in various industries, including pharmaceuticals, food and beverage, and plastics. It plays a significant role in the production of acetic acid, perfumes, and other valuable chemicals. Establishing an “Acetaldehyde Manufacturing Plant” involves detailed planning and execution to ensure successful operations. This Acetaldehyde Manufacturing Plant Project report provides a comprehensive guide to setting up an acetaldehyde manufacturing facility, covering aspects from market analysis and plant design to production processes and financial considerations. Whether you’re an entrepreneur or an investor, this guide will help you navigate the complexities of launching an acetaldehyde manufacturing business.

Project Overview

Objectives

The main objectives of setting up an acetaldehyde manufacturing plant are:

- To produce high-quality acetaldehyde that meets industry standards and customer requirements.

- To develop a cost-effective and efficient production process.

- To establish a strong market presence and achieve growth in the chemical industry.

Market Research

Conducting thorough market research is essential for understanding the demand and opportunities in the acetaldehyde market. Key areas to explore include:

- Market Demand: Analyze the current and projected demand for acetaldehyde in various applications, including its use in producing acetic acid, perfumes, and plastics.

- Competitor Analysis: Investigate existing acetaldehyde manufacturers to understand their market position, product offerings, and competitive advantages.

- Consumer Preferences: Identify what features and qualities customers value in acetaldehyde, such as purity, stability, and cost.

Get a Free Sample Report with Table of Contents @

Plant Setup

Location

Selecting the right location for your acetaldehyde manufacturing plant involves several considerations:

- Proximity to Raw Materials: Being close to suppliers of feedstock like ethanol or ethylene can reduce transportation costs and improve supply chain efficiency.

- Access to Markets: Choose a location with good logistical access to your target customers and markets.

- Regulatory Environment: Ensure that the location complies with local regulations and offers a favorable business climate.

Facility Design

Designing the facility is crucial for efficient operations:

- Production Areas: Allocate space for the production unit, including reactors, separation units, and storage tanks.

- Storage: Designate areas for storing raw materials, intermediate products, and finished acetaldehyde.

- Utilities: Ensure adequate provisions for utilities such as electricity, water, and steam.

- Safety: Implement robust safety measures to protect workers and comply with health and safety regulations.

Equipment

Invest in high-quality equipment to ensure efficient and safe production:

- Reactors: For the chemical reaction needed to produce acetaldehyde from ethanol or ethylene.

- Distillation Columns: For separating acetaldehyde from other by-products and impurities.

- Storage Tanks: For storing acetaldehyde and other chemicals used in the process.

- Quality Control Instruments: To monitor the purity and quality of acetaldehyde.

Production Process

Raw Material Sourcing

Secure reliable sources for raw materials:

- Ethanol or Ethylene: The primary feedstocks used in the production of acetaldehyde.

- Catalysts: Such as those used in the oxidation process of ethanol or ethylene.

- Additives: For stabilizing acetaldehyde and ensuring its quality.

Manufacturing Steps

- Feedstock Preparation: Prepare ethanol or ethylene for the production process.

- Chemical Reaction: Use a reactor to convert ethanol or ethylene into acetaldehyde through an oxidation reaction.

- Separation and Purification: Employ distillation and other separation techniques to isolate acetaldehyde from by-products and impurities.

- Quality Control: Test the acetaldehyde to ensure it meets industry standards and specifications.

- Packaging and Storage: Package the finished acetaldehyde in appropriate containers and store it safely until distribution.

Compliance and Certification

Ensure compliance with relevant regulations and standards:

- ISO Certification: For quality management systems.

- Environmental Regulations: Adhere to regulations related to emissions, waste management, and chemical handling.

- Health and Safety Regulations: Implement measures to ensure the safety of workers and facilities.

Marketing and Distribution

Branding

Develop a strong brand identity to differentiate your acetaldehyde in the market:

- Brand Name and Logo: Create a distinctive brand name and logo that reflects the quality and reliability of your product.

- Product Positioning: Emphasize features such as purity, consistency, and competitive pricing in your marketing materials.

- Marketing Strategy: Utilize digital marketing, industry trade shows, and networking to promote your acetaldehyde.

Distribution Channels

Establish effective distribution channels to reach your target customers:

- Direct Sales: Engage directly with large industrial clients and chemical companies.

- Distributors: Partner with distributors to expand your reach and access different markets.

- Online Platforms: Consider e-commerce options to reach a broader audience and facilitate orders.

Financial Considerations

Budgeting

Develop a detailed budget covering:

- Initial Investment: Costs for facility construction, equipment, and initial raw materials.

- Operational Expenses: Ongoing costs such as labor, utilities, maintenance, and raw materials.

- Marketing and Distribution: Allocate funds for promotional activities and distribution logistics.

Funding

Explore various funding options:

- Bank Loans: Secure loans from financial institutions to finance your plant setup.

- Investors: Attract venture capital or angel investors interested in the chemical industry.

- Grants and Incentives: Look for government grants or subsidies for manufacturing projects.

FAQs

What are the primary uses of acetaldehyde?

Acetaldehyde is used primarily in the production of acetic acid, which is a key ingredient in many industrial processes. It is also used in the manufacture of perfumes, flavorings, and as an intermediate in various chemical syntheses.

How long does it take to set up an acetaldehyde manufacturing plant?

The setup time for an acetaldehyde manufacturing plant typically ranges from 12 to 24 months. This includes time for facility construction, equipment installation, and obtaining necessary permits and certifications.

What are the main challenges in establishing an acetaldehyde manufacturing plant?

Key challenges include securing reliable raw material suppliers, managing production costs, ensuring compliance with environmental and safety regulations, and developing a robust marketing and distribution network.

What certifications are required for acetaldehyde manufacturing?

Essential certifications include ISO for quality management systems, compliance with environmental regulations, and adherence to health and safety standards.

How can I ensure the quality of acetaldehyde produced at the plant?

Ensure quality through rigorous testing during production, adherence to industry standards, and regular audits. Invest in quality control equipment and employ skilled personnel to maintain high manufacturing standards.

Media Contact:

Company Name: Claight Corporation

Contact Person: Lewis Fernandas, Corporate Sales Specialist — U.S.A.

Email: sales@expertmarketresearch.com

Toll Free Number: +1–415–325–5166 | +44–702–402–5790

Address: 30 North Gould Street, Sheridan, WY 82801, USA

Website: www.expertmarketresearch.com

Aus Site: https://www.expertmarketresearch.com.au/